-

SERVICE LIFE OF 30 YEARS WITH 65 MPa STRENGTH

SERVICE LIFE OF 30 YEARS WITH 65 MPa STRENGTH -

98% COMPRESSION RATE UP TO 35 cm IN A SINGLE LAYER

98% COMPRESSION RATE UP TO 35 cm IN A SINGLE LAYER -

DAILY 10,000M2 MANUFACTURING CAPABILITY

DAILY 10,000M2 MANUFACTURING CAPABILITY

What is Highly Compressed Concrete (HCC) Pavement?

Properties of Highly Compacted Concrete (YSB) Coatings

- Compressed thickness up to 35 cm in a single layer

- Straight slab edges without using formwork

- 98% compression ratio

- Flexural strength up to 5.5 MPa

- Compressive strength up to 60 MPa

- Density of 2500 kg/m3 and above

- Low IRI value

- High ride comfort

Advantages of Highly Compressed Concrete (YSB) Coatings

- Applied today, opened to traffic tomorrow.

- It has a long service life of up to 25 years.

- Requires very low maintenance and repair.

- Has high strength and durability.

- No need for formwork and reinforcement.

- Provides 10,000 m2 construction opportunity per day.

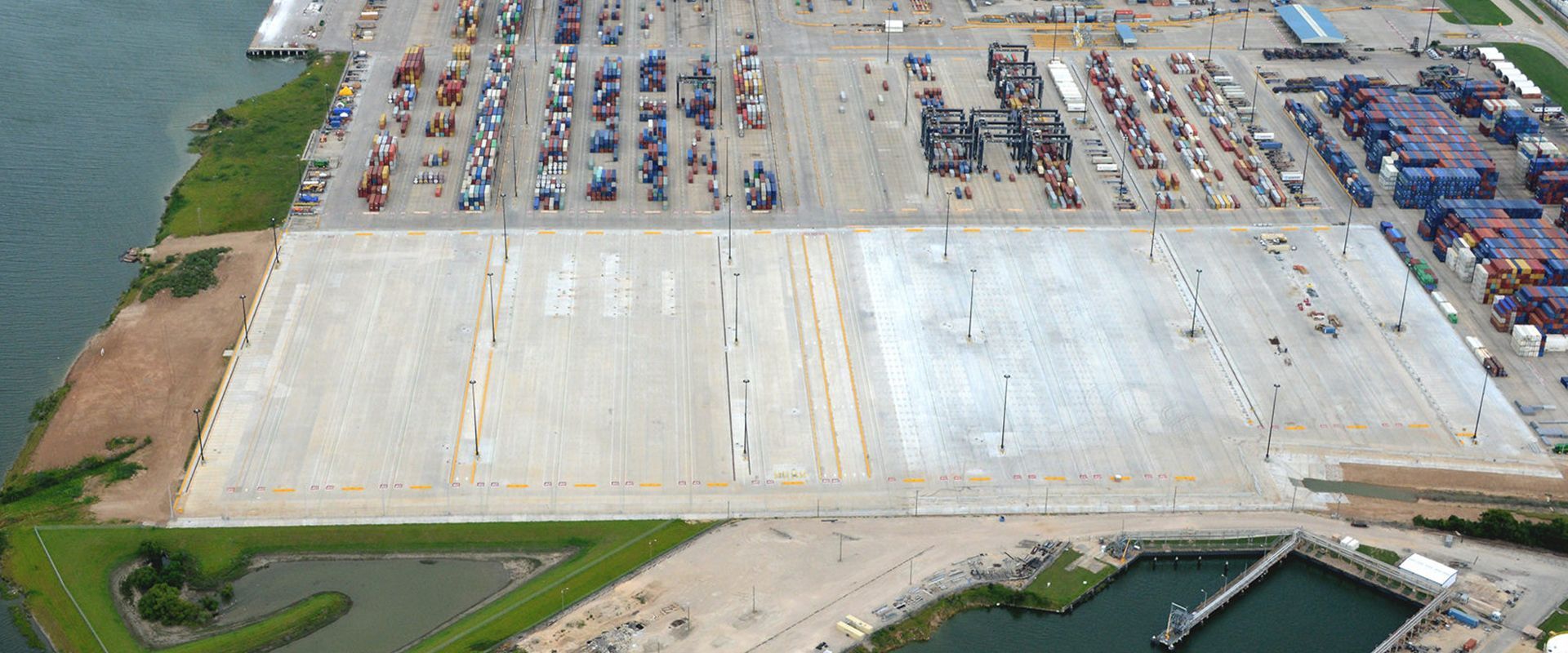

Highly Compressed Concrete (YSB) Coating Usage Areas

- Ports

- Industrial areas

- Military facilities

- Storage areas

- Roads

ECONOMIC PERMANENT SOLUTION

- No reinforcement or formwork is used in YSB coatings. Despite this, it has 65% higher compressive strength than traditional concrete.

- Labor is minimized and the entire process is done with special equipment. Labor cost is very low.

FAST PRODUCTION

- In YSB coatings, 98% compression ratio up to 25 cm in a single layer is achieved without the need for a roller.

- As long as concrete supply is provided, an average of 10,000 m2 of production can be done in an 8-hour work.

- YSB coatings are opened to traffic within 24 hours.

HIGH DURABILITY

- The concrete mixture of YSB coatings is quite different from other types of concrete.

- The void ratio is reduced to 1% with the latest technology equipment used.

- In this way, it is much superior to all concrete and asphalt coating types in terms of durability features such as freeze-thaw resistance and resistance to environmental effects. has a performance.

-

What are the advantages of concrete roads?

Concrete roads are distinguished by their high strength and durability, long service life, and low maintenance and repair needs throughout their lifespan. Additionally, their high load-bearing capacity, resistance to deformation under heavy traffic, non-combustible inorganic structure, and environmental benefits in combating global climate change contribute to their widespread use around the world.

-

What are the first examples of concrete roads in the world?

The world's oldest concrete road is Court Avenue in the state of Ohio, USA, which has been in service since 1891. This concrete road has continued to serve for 133 years.

Australia is one of the early adopters of concrete road technology. The Victoria Parade, built in Melbourne in 1928, is recognized as Australia's first concrete road project.

In Germany, the first concrete road was constructed in 1888 in the city of Wroclaw, which is now within the borders of Poland. Therefore, it can be said that concrete roads have been successfully used worldwide for over 100 years.

-

What are the first examples of concrete roads in Turkey?

The first concrete road in Turkey was constructed in 1953 in Sinop, serving a facility with heavy traffic loads such as the NATO Radar Base. Despite being over 80 years old, this concrete road continues to function without interruption and without the need for maintenance or repair.

Similarly, the first concrete roads built in Trabzon in 1958 and Adana in 1959 stood out for their high durability and low maintenance costs, paving the way for Turkey's concrete road network, which now spans over 21,000 kilometers.

-

What is the lifespan of concrete roads?

Well-designed and properly constructed concrete roads typically have a lifespan of 30 to 50 years. This duration can vary depending on factors such as construction quality, appropriate design, environmental conditions, and the intended use.

-

What are the environmental benefits of concrete roads?

Increasing construction on the Earth reduces glaciers, soil cover and trees with high albedo values, while increasing dark structures with low albedo values. This causes the sunlight coming to the Earth to be absorbed by dark structures with low albedo, causing temperature increases and urban heat island formation.

Concrete roads have 3 times higher albedo values compared to asphalt roads. This allows them to reflect a significant portion of the sunlight coming to them back to the atmosphere. Therefore, concrete roads help reduce environmental temperatures by reflecting more sunlight, slow down the warming of the Earth and play an important role in combating global climate change by minimizing the urban heat island effect.

-

How is the load-bearing capacity of concrete roads?

Due to their rigid pavement structure, concrete roads act like a beam, distributing the loads applied to them over a wider area before transferring them to the underlying layers. As a result, concrete roads are known to have a significantly higher load-bearing capacity compared to alternatives. This makes concrete roads the ideal solution for areas with high heavy vehicle traffic, such as ports, industrial zones, and heavily trafficked roads.

-

What is Roller-Compacted Concrete (RCC) pavement?

Roller-Compacted Concrete (RCC) pavement is a type of rigid pavement constructed by mixing aggregate with the appropriate proportions of water and cement in a concrete plant. The mixture is then laid using pavers and compacted with rollers to create a durable and stable surface.

-

Where is Roller Compacted Concrete (RCC) Used?

Roller Compacted Concrete (RCC) is utilized in military bases, industrial areas, storage facilities, ports, and roads. RCC offers many technical and economic advantages compared to alternative paving methods.

-

What are the Advantages of Roller Compacted Concrete (RCC)?

Roller Compacted Concrete (RCC) has a zero slump value due to its low water content. Compared to traditional concrete mixes, RCC has approximately 40% less water, resulting in a water-cement ratio as low as 0.30. This contributes to a significant increase in 28-day compressive strengths, up to 70-80%, even with the same cement dosage.

RCC stands out for several advantages, including the absence of reinforcement, rapid construction, quick traffic opening, no need for additional surface treatments, and cost-effectiveness. Additionally, its open surface color provides environmental benefits by enhancing traffic safety in rural areas and reducing electricity consumption for lighting.

-

How is the Freeze-Thaw Resistance of Roller Compacted Concrete (RCC)?

RCC has nearly four times fewer voids compared to traditional concrete mixes. A properly designed and correctly constructed RCC mixture contains approximately 1.5% by volume of voids. Additionally, unlike traditional concrete, the voids in RCC are isolated from each other.

As a result, RCC has a much lower void ratio and the voids are independent of each other, leading to significantly higher freeze-thaw resistance compared to alternatives.

RCC pavements are particularly suitable for cold climates and regions with high seasonal temperature fluctuations and significant temperature differences between day and night.

-

What are the Advantages of High-Density Pavers?

The compaction ratio achieved is one of the most critical factors influencing the durability performance of RCC pavements. In regions with cold climates and significant day-night temperature fluctuations, achieving high freeze-thaw resistance in RCC requires compaction rates up to 98%. Therefore, the high compaction achieved with high-density pavers maximizes the pavement's resistance to environmental effects throughout its long service life.

Additionally, high-density pavers reduce the need for subsequent compaction and eliminate undulations that can diminish driving comfort. In traditional (normal) density pavers, free material often tends to be displaced after placement, especially at the edges of the slab. However, high-density pavers, with their pressing beams providing high compaction, construct the edges of the pavement almost as if forming a mold, resulting in vertical, well-formed edges.

-

Where are High-Density RCC Pavements Used?

In the United States, which has been using RCC technology for nearly 100 years, 95% of RCC pavements constructed since 2016-2017 have been built with high-density pavers. High-density RCC pavements are commonly used in ports, military bases, and industrial areas where heavy loads are transported, as well as on highways where high levels of comfort are desired.

-

14 Nov 2025Why Concrete Roads

14 Nov 2025Why Concrete RoadsRoads are the lifeblood of modern societies. Every day, millions of people and vehicles use roads to ensure safe and comfortable transportation. Safe, durable, and sustainable roads are an indispensable part of both economic development and daily life.

-

14 Nov 2025Increasing Urbanization and Climate Change

14 Nov 2025Increasing Urbanization and Climate Change -

14 Nov 2025Permanent and Cost-Effective Solution for SSB Roads

14 Nov 2025Permanent and Cost-Effective Solution for SSB RoadsRoller-compacted concrete (RCC) is a type of concrete produced by mixing aggregate with a suitable amount of water and cement at a ready-mix concrete plant. It has a zero slump due to its low water content. With approximately 40% less water compared to

-

26 Sep 201927th European Young Geotechnical Engineers Conference

26 Sep 201927th European Young Geotechnical Engineers Conference27th EYGEC will be held on 26-27th September, 2019 at Kefaluka Resort Hotel Bodrum, Muğla-Turkey.